JIUWU company produces the ceramic ultrafiltration membranes with the pore size 20nm, 50nm and so on with reasonable uf membrane price. JIUWU company offers a large choice of ceramic uf membranes with different geometries and cut-offs to meet your process requirements in viscosity, molecule size, impurity profile, purity and yield target, etc. as well as cleaning and sanitization procedures. So our ceramic ultrafiltration membrane ensures a reliable and long-lasting purification system. Ceramic ultrafiltration membranes are better than those membranes in ceramic membrane filtration systems. Our UF membrane water filter won't let you down!

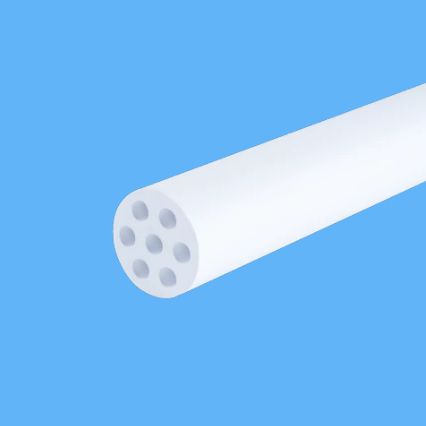

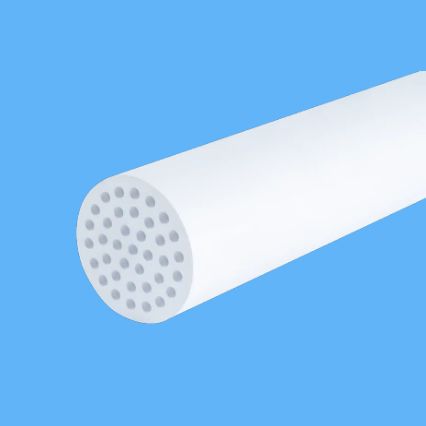

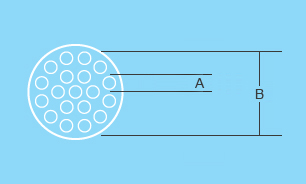

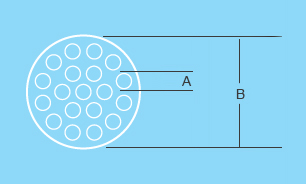

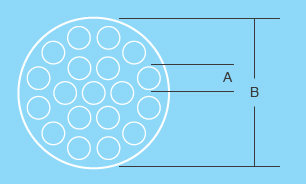

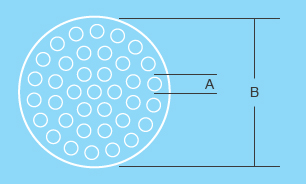

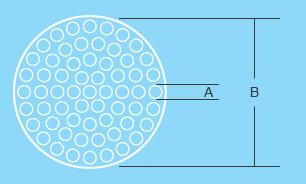

| Pictures | Size | Pore size |

| A: 3.3mm | 50nm |

| B: 25mm | ||

| A: 4.0mm | 50nm |

| B: 30mm | 20nm | |

| A: 6.0mm | 50nm |

| B: 40mm | ||

| A: 3.6mm | 50nm |

| B: 40mm | ||

| A: 2.5mm | 50nm |

| B: 40mm |

Ultrafiltration ceramic membrane/ceramic filter is a variety of membrane filtration in which forces, such as pressure or concentration gradients, cause separation through the semi-permeable membrane. High molecular weight suspended solids and solutes remain in the so-called retentate while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). The pore size of the ultrafiltration ceramic membrane is in the range of 0.01μm ~ 0.05μm, suitable for the separation, concentration, and purification of macromolecules and small molecules.

A versatile and economical solution for clarification, concentration, and purification of liquids, ultrafiltration membrane filter could remove emulsified oils, metal hydroxides, colloids, bacteria and viruses, emulsions, dispersed material, suspended solids, and other large molecular weight materials from water and other solutions. Ultrafiltration ceramic membrane also serves in critical parts of the production processes of fruit juice, milk and whey, electrocoat paints, pharmaceuticals, poly-vinyl alcohol, and indigo dye. It is key to surface water treatment for potable uses and wastewater treatment for reuse, such as palm oil wastewater and paper mill wastewater treatment. Ultrafiltration ceramic membrane is used to recycle flow or add value to later products and more. In many cases, ultrafiltration ceramic membrane is used for prefiltration in reverse-osmosis plants to protect the reverse-osmosis process. Ultrafiltration ceramic membrane is an effective means of reducing the silt density index of water and removing particulates that can foul reverse osmosis membranes.

Ultrafiltration is a separation process that uses a membrane to filter out impurities from a liquid. The ultrafiltration membrane is a type of semipermeable membrane that allows some molecules and ions to pass through while blocking others based on their size and charge.

The ultrafiltration membrane works by using a pressure gradient to force the liquid to flow through the membrane. The membrane has tiny pores that are small enough to block particles and molecules above a certain size, while allowing smaller molecules and ions to pass through.

As the liquid passes through the ultrafiltration membrane, the impurities are filtered out and retained on the feed side of the membrane, while the purified liquid passes through the other side of the membrane. The degree of purification depends on the size and charge of the molecules and ions being filtered, as well as the pore size and surface chemistry of the membrane.

Ultrafiltration membranes are commonly used in water treatment, food and beverage processing, pharmaceutical manufacturing, and other industries where the removal of impurities is critical.

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español Contact Us

Contact Us