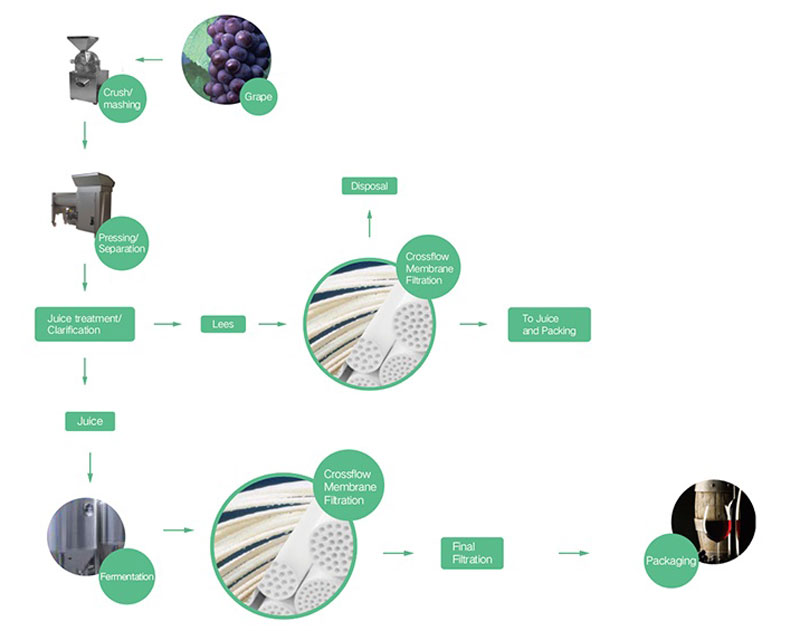

Membrane crossflow filtration is becoming the unique alternative to kieselguhr filters in wine industry with the developments in environmental and health regulations.

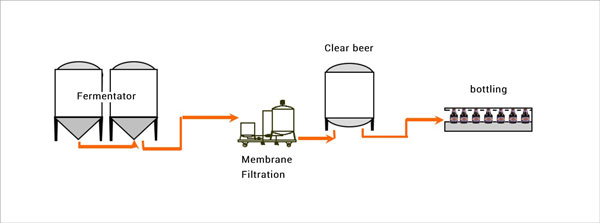

Membrane crossflow filtration is widely used in wine membrane filter system for wine filtration, especially as the red wine filter. It can also be used for cross flow filtration beer. Now, the membrane crossflow filtration technology potential for energy-efficiency has made it a viable technique for the clarification of wine and other beverages.

Crossflow filtration uses a selectively porous ceramic membrane that filters a liquid in order to purify or clarify it. The quality of the filtration is constant over time because the fouling is reduced because the filtering is made without any change of state of the filtered element, and never gets distorted. Membrane crossflow filtration is one of the environmentally-friendly wine filtration systems. During the filtration, no filter aid is used. In one step, crossflow filtration clarifies the wine, giving it a clear appearance and making the wine microbiologically stable. So it has very strong advantages in simplifying the steps before bottling and reducing or eliminating the need for some consumables.

Advantages:

Stable filtrate quality

Maximum guarantee the sensory properties of the wine

Optimized process

No filter aids required

High yield

Reduced filtration costs & product losses

Smart, compact, small footprint

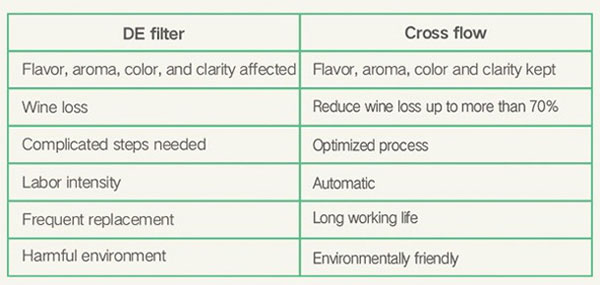

Comparison:

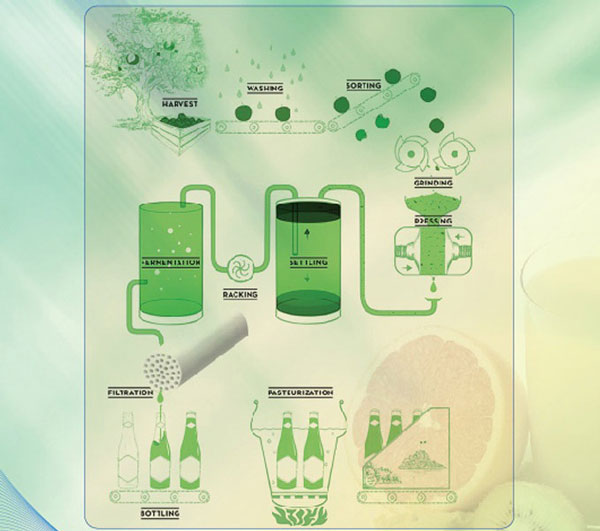

Cider is an alcoholic beverage made from the fermented juice of apples.

Cider is popular especially in the West Country, and widely available. The UK has the world's highest per capita consumption, as well as its largest cider-producing companies.

Cider alcohol content varies from 1.2% ABV to 8.5% or more in traditional English ciders, and 3.5% to 12% in continental ciders.

Perry is a similar product made from fermented pear juice.

Process

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español