Membrane separation technology

The so-called filtration usually refers to a unit operation that allows liquid to pass through a porous medium while separating the solid matter contained therein. Membrane filtration technology relies on a certain operating pressure (usually 0.1-0.7MPa) and surface flow rate under the condition of no phase change to carry out macromolecular substances or solid particles and small molecular substances or liquids physically separation on the surface of a semi-permeable membrane, so as to achieve the purpose of material-liquid separation.

Larger diameter particles, microorganisms, etc., are intercepted during the filtration process. Therefore, this technology has the advantages of clarification, sterility, continuous operation, no need to add filter aids, and products without contamination. The filtrate obtained in production has good brightness and pure color.The original color, aroma and taste substances in the fresh milk are maintained, and the sensory indicators are better.

Membrane microfiltration technology can replace pasteurization and chemical preservatives, effectively intercepting bacteria, yeasts and molds in dairy products, allowing the effective ingredients in dairy products to penetrate, and has the advantage of cold sterilization. Fresh milk is skimmed, and the skim milk is filtered through a microfiltration membrane. Finally, the filtered and sterilized skim milk is sterilized at 80℃/6s to inactivate the enzymes in the milk and avoid the degradation of the milk caused by the decomposition of protein during storage. This adopted process can be kept fresh at room temperature and has the same taste as sterilized milk.This compound sterilization system that combines membrane technology with other technologies reduces the heat treatment intensity of milk, while ensuring the sterilization effect, it can also maintain the original flavor of fresh milk and avoid thermal denaturation of protein, effectively Improve the quality and shelf life of products.

Now, in the developed areas of the international dairy industry, the process of combining microfiltration membrane filtration technology with pasteurization or high temperature sterilization to produce ESL milk has been industrialized. Therefore, the application of membrane microfiltration technology in dairy industry is of great significance.

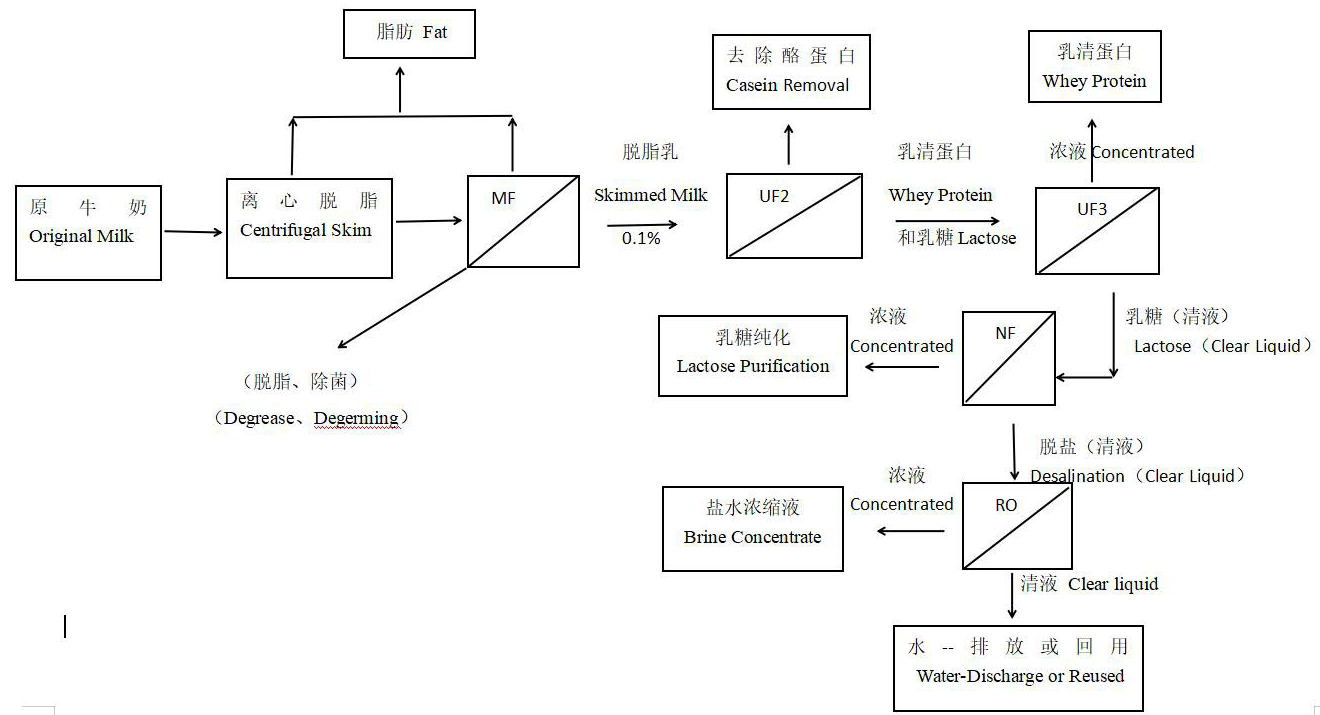

Membrane separation technology has a wide range of applications in the dairy industry, and has the advantages of simplifying the production process, reducing energy consumption, reducing wastewater pollution, and improving the comprehensive utilization of dairy products. At present, the application of membrane technology in the dairy industry mainly includes: concentration of milk slurry, concentration of milk, production of fresh cheese, standardization of milk, protein fractionation, filtration of brine, desalination of whey, and sterilization of dairy products.

Skimmed milk filtration

Skimmed milk is to remove part of fat in normal milk, so that the fat content is reduced to less than 0.5%, less than 1 / 7 of the fat content of ordinary milk.The skimmed milk here refers to the whole skimmed milk, which is relative to the whole milk. There is low-fat milk in between. The production of this kind of milk meets the nutritional needs of modern people in pursuit of "high protein and low fat".The production of skimmed milk is due to people's special needs for dietary health. Whether people with cardiovascular disease, middle-aged and elderly people, or women who want to lose weight, they all regard it as the "ideal food" that can ensure nutrition and effectively control fat intake.

At present, there are pasteurized milk, sterilized milk, sour milk, milk beverage, milk powder, condensed milk, cheese, ice cream, cream, whey powder, lactose, casein, etc., but the production volume is very small. Pasteurization in milk production process is mainly to reduce the harm of microorganisms and pathogenic bacteria that may appear in raw milk on human health. But pasteurization can't kill all the bacteria, it can reduce the number of bacteria to a level that is not harmful to the human body.

Fig1. Skimmed milk classification process

Dairy sterilization

Membrane separation technology has the advantage of cold sterilization. The bacteria and spores can be trapped through the micropores to realize the sterilization of dairy products. Microfiltration technology can replace pasteurization and chemical preservatives, effectively intercepting bacteria, yeasts and molds in dairy products, and allowing effective ingredients in dairy products to penetrate. The microfiltration technology has low energy consumption and avoids high temperature heating, and the fresh milk almost maintains the original flavor. Cross-flow filtration technology (membrane pore size is 1~1.5μm) is used to remove bacteria in low-fat and medium-fat milk, and its sterilization rate is >99.6%.

Whey Desalting

Nanofiltration membrane can remove all the solutes in whey and permeate monovalent ions. The permeate side substances include water, monovalent salts and some organic acids with a tetrahedral structure similar to water molecules. Using nanofiltration technology, the permeate after whey and ultrafiltration membrane treatment can be effectively concentrated and ash removed. After the whey wastewater is passed through the new membrane process, not only can the whey protein and oligosaccharides in the wastewater be recovered, but also zero discharge of wastewater from soybean production can be achieved.

Features of membrane concentration and separation

1. Low energy consumption, so that the operating cost of the equipment is low.

2. The equipment is small in size and simple in structure.

3. Reduce wastewater pollution and comprehensive utilization of by-products, etc.;

4. The process is simple and easy to operate and manage.

5. The substance does not undergo qualitative changes during the separation process (that is, it does not affect the molecular structure of the material).

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español