At present, oily wastewater has caused serious pollution and damage to the environment due to high chemical oxygen consumption and high oil content. Environmental protection, oil recycling, water purification, and pollution-free discharge all require effective purification and separation of oily wastewater. Membrane separation is an emerging high-efficiency separation technology. Compared with traditional chemical methods, it has the advantages of small footprint, easy operation, reasonable treatment costs, and production of high-quality water, making it a very competitive oily wastewater treatment technology. Membrane separation technology means to remove impurities of certain particle sizes in sewage through physical interception. Its working principle is as follows: driven by external pressure, substances with a particle size smaller than the pore size of the membrane can reach the other side of the membrane through the micropores on the membrane filter layer, while substances with a larger particle size are intercepted. In this way, different particle sizes in the solution can be screened to achieve selective permeability to different substances. The treatment effect of membrane separation technology on oily wastewater will be affected by the following factors to a certain extent, including membrane flux, temperature, and aeration volume. For example, the higher the temperature, the slower the membrane fouling speed, and the smaller the change in transmembrane pressure difference, which is conducive to the stability of membrane flux. In recent years, the research and application of ceramic flat sheet membranes for the treatment of oily wastewater have also received increasing attention.

The ceramic flat sheet membrane is a new generation of technology that uses inorganic materials (such as Al2O3, ZrO2, TiO2, SiO2, SiC) manufactured through the traditional Chinese sintering process with thousands years of history. The ceramic flat sheet membrane has many advantages such as large filtration area, high separation efficiency, stable effect, good chemical stability, acid and alkali resistance, organic solvent resistance, bacteria resistance, high-temperature resistance, pollution resistance, high mechanical strength, good regeneration performance, easy separation process, low energy consumption, easy operation and maintenance, long service life, etc. It will play a key role in important fields such as energy, resources, environment, and health care, and its application market involves many fields such as the food industry, chemical engineering, and petrochemical engineering, biomedicine, environmental protection, and energy.

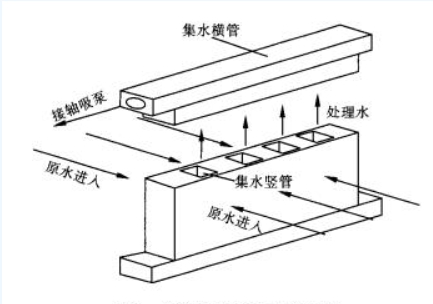

The working principle of the ceramic flat sheet membrane is shown in Figure 1. The inside of the membrane is provided with vertical water collection pipe, and both ends of the membrane are provided with horizontal water collection pipe. One end of the horizontal water collection pipe mouth is connected with the suction pump, and the raw water enters from the surface on both sides of the membrane under the suction of the pump. At the same time, the large-sized suspended solids, oil, and other impurities in the raw water are trapped on the surface of the membrane to achieve the purpose of removing pollutants. The treated water merges from the vertical water collection pipe into the horizontal water collection pipe and is pumped out by the pump.

Figure 1 Schematic diagram of the working principle of ceramic flat sheet membrane

The oily wastewater is pretreated to remove visible oil, sludge, and other particulate pollutants so that the pretreated wastewater can meet the requirements of the ceramic flat sheet membrane feedstock. The pretreated wastewater then goes to the ceramic flat membrane degreasing system for filtration treatment, and the oil and suspended particles in the wastewater are removed to meet the requirements of the subsequent biological wastewater treatment process. The ceramic flat sheet membrane adopts a cross-flow filtration operation mode, namely the wastewater passes through the membrane surface in parallel; Small molecules pass through the membrane; Large molecules are intercepted; The trapped substances are continuously carried away from the membrane surface by the fluid so that the membrane is not easily clogged, and thus the equipment runs longer, also the cleaning is easier. Since most of the oily wastewater is relatively poor in chemistry, with the continuous development of production technology, the membrane separation technology therefore has been widely used. Membrane separation technology is simple in operation, short in process, and features good separation effects, and also has the advantages of relatively high processing efficiency and low energy consumption.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español