The rise of the tea beverage industry has promoted the deep processing of tea. Developing tea extracts that are easy to use and able to maintain its flavor is of great significance for making full use of tea resources, improving the economic benefits of the tea industry, and expanding the domestic and foreign markets of tea. Deep processing of tea mainly refers to taking fresh tea leaves, dried leaves, tea seeds, pruned leaves and others as raw materials to make food. With the continuous research and development of food processing technology, the quality of deep processing of tea is gradually improving.

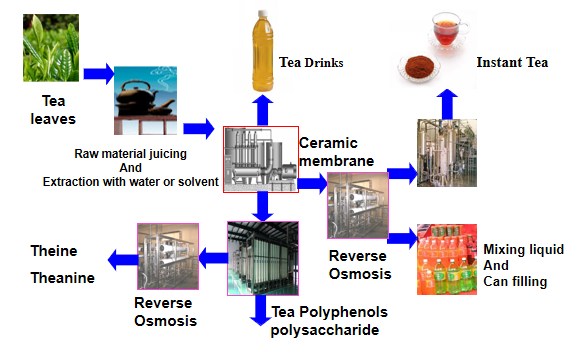

In the production process of traditional green tea beverage, most of the energy consumed is to clarify the tea beverage. Cream down of tea liquid is the main reason that affects the clarity of tea beverages, whose main factor is tea cheese, which dissolves at high temperatures and becomes insoluble when the temperature decreases, thus, cream down appears. We will find this phenomenon when we drink tea in our daily life, such as when cooling the tea for a period of time. The use of a 50nm ceramic membrane can significantly improve the clarification of the green tea extract, which can ensure a high retention rate of the effective flavor components of the tea juice under appropriate process parameters and reserve most of the polymer substances that are prone to precipitation with good quality. Moreover, using the ceramic membrane helps enterprises to enhance the market competitiveness of tea drinks and brings higher economic benefits to enterprises.

Ceramic membrane technology can also achieve clarification and filtration of tea soup, concentration at room temperature, sterilization and decolorization, and separation and purification of crude polyphenols during the filtration of instant tea beverages. Ceramic ultrafiltration membrane technology is different from traditional filter elements, diatomaceous earth, plate and frame and other filtration methods. It has high filtration accuracy and stable filtration performance, and it can effectively intercept and remove the dissolved colloid, fiber, protein and other macromolecular impurities in the tea soup. The filtrate has high clarity and purity. The membrane concentration system can realize the concentration of tea soup under the conditions of normal temperature and low energy consumption. The concentrated tea juice can be directly dried to obtain instant tea powder after concentration, which ensures that the aromatic substances of the tea are not damaged during the production process, and finally obtains the fragrant instant tea powders. The application of ceramic membrane technology in the filtration process of instant tea beverages has effectively improved the quality of instant tea beverages and helped manufacturers to gain a foothold in the fiercely competitive market. Ceramic membrane technology has won the favor of the majority of users.

In the deep processing of tea, concentration is a necessary procedure for drying. Its purpose is to recycle organic solvents or remove water so as to prepare high-concentration tea concentrates or extracts. Concentration of using reverse osmosis membrane technology is superior to that of traditional vacuum evaporation in terms of product yield and clarity, the reason is that reverse osmosis membrane technology has the advantages of no phase transition, short term, being able to be carried out at room temperature, which reduces the loss of heat-sensitive substances and volatile substances in the feed liquid system. And reverse osmosis membrane low temperature concentration of green tea juice fully reflects this feature. Since green tea juice is rich in nutritional and health care substances such as chlorophyll and polyphenols, these components are easy to oxidize and brown. However, the application of reverse osmosis membrane low-temperature concentration method can industrially produce the clear and yellow-green bright tea with original green tea flavor.

With the development of economy and science, the deep processing of tea has transformed from a single tea beverage product to a diversified product. Scientific deep processing technology is conducive to the development of the tea deep processing industry, and it is more conducive to the improvement of people's living standards. The application of membrane separation equipment in the deep processing of tea has been recognized by the majority of users, creating higher economic benefits for tea deep processing enterprises.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español