Animal Blood Filtration

Animal blood contains almost all nutrients and elements that human body needs, including protein, amino acids, vitamins and other nutrients, such as sodium, potassium, iron, calcium and other trace elements.

In traditional techniques, the most blood is abandoned which causes resources waste, exceptionally a little is used in feed production. As a kind of living iron supplement, heme-iron, whose absorption is high and side effects are small can be absorbed by the cells of the mucous membrane of the intestine directly without stimulating.

To extract heme-iron from animal blood has a great value for development. SOD (superoxide dismutase) is also extracted from animal blood.

Cell culture

Cell culture is the process by which cells are grown under controlled conditions, generally in an cell culture equipment.

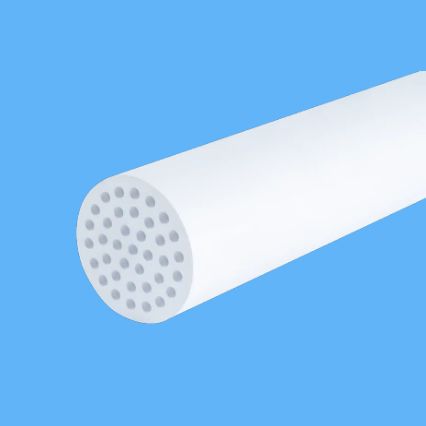

Ceramic membrane filtration is frequently used in animal cell culture for bioreactor harvesting, protein concentration, buffer exchange, virus filtration, and sterile filtration. A variety of membrane materials and pore sizes ranging from loose

ceramic microfiltration membranes to tight ultrafiltration membranes, which reject small proteins, are frequently found in a purification train. While all of these operations make use of the same size-based separation principle, the actual methods of operation vary significantly.

Microfiltration is often the first of the unit operations in the purification train. Microfiltration membranes have pores in the micrometer size range. Microfiltration is used to remove cells and cell debris. This chapter begins by describing tangential flow microfiltration. A typical method of operation is included.

Concentration of the product and buffer exchange is often required toward the end of the purification train. Ultrafiltration membranes are used for both operations. The theory of tangential flow ultrafiltration is briefly described followed by a typical method of operation.

Today, large-pore ultrafiltration membranes (molecular weight cutoff 100–500 kDa) are finding increasing applications for virus filtration. Validation of virus cleaner is a major concern in the biopharmaceutical industry. At the same time, purification of virus particles for viral vaccines and applications in gene therapy is a major separations challenge.

Vaccine

A vaccine is a biological preparation that provides active acquired immunity to a particular disease.

Vaccine ingredients are derived from a variety of sources including tissue extracts, bacterial cells, virus particles, recombinant mammalian, yeast, and insect cell-produced proteins and nucleic acids. The most common method of vaccine production is based on an initial fermentation process followed by purification.

Production of vaccines is a complex process involving many different steps and processes. Selection of the appropriate purification method is critical to achieving desired purity of the final product. Clarification of vaccines is a critical step that strongly impacts product recovery and subsequent downstream purification.

There are several technologies that can be applied for vaccine clarification. Selection of a harvesting method and equipment depends on the type of cells, product being harvested, and properties of the process fluids. These techniques include membrane filtration (microfiltration, tangential-flow filtration), centrifugation, and depth filtration (normal flow filtration). Historically vaccine harvest clarification was usually achieved by centrifugation followed by depth filtration.

Recently membrane based technologies have gained prominence in vaccine clarification. The increasing use of single-use technologies in upstream processes necessitated a shift in harvest strategies.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español