Although batch processes are currently used, a number of more advanced techniques have been investigated in order to improve the process efficiency of organic acid fermentation. Promising every result must have been achieved using the tangential flow filtration in the continuous fermentation systems.

One of the main advantages of tangential flow filtration is that the higher biomass concentrations are possible because cells are continuously recycled back to the fermentor. A dense population of cells not only accelerates production of lactic acid but also minimizes contamination by foreign microorganisms. Thus high cell density continuous systems could increase the efficiency of lactic acid production. It can also be applied to nictric acid production.

Lactic acid fermentation broth on the main performance of the membrane fouling is

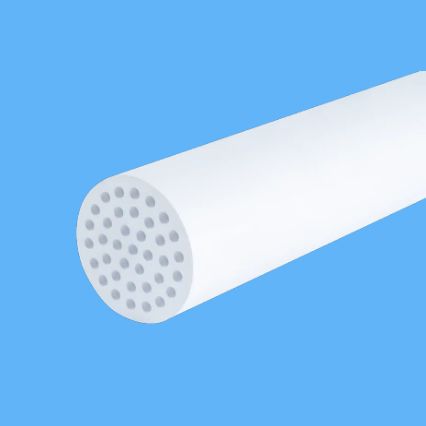

A. Gel polarization fouling of, membrane surface. Lactic acid fermentation broth by centrifuge coarse filters, except for a small amount of mycelium and solids, but also contains a lot of protein, sugar and easily carbonized material. During the membrane filtration process of lactic acid purification, these substances are easily deposited on the membrane surface and formed gel polarization fouling.

B. Membrane pore adsorption, crystallization pollution. Adding an excess of calcium carbonate is to adjust the system pH, in this way, the excess calcium carbonate is easily occurred crystallization within the hole and in the membrane surface. In the actual operation, the pipeline can easily generate a short temperature difference due to the solubility of calcium lactate which is very sensitive to temperature, so the calcium lactate is also vulnerable to precipitation surface or deposition within the membrane hole and in the membrane surface.

In order to remove impurities, ceramic membrane contamination mechanism in the process of lactic acid fermentation comes down to mycelium, protein, sugar and gel polarization pollution caused by carbonized material in the membrane surface of the and crystallization pollution of calcium carbonate - calcium lactate within the hole and membrane surface. Reasonable cleaning membrane procedure is

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español