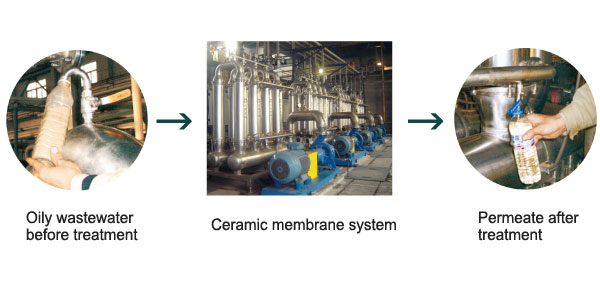

In the production process of rolling, galvanizing, spraying, metal cutting, oil and alkali refining, a large amount of oily wastewater is produced. JIUWU company has been successfully applied to the treatment of oily wastewater with ceramic membrane technology, and there are many typical cases. JIUWU company can provide the overall process package of emulsified oil wastewater treatment, including the oily water filtration system.

The advantages of ceramic membrane process:

Acid/alkaline/oxidation chemicals resistance

Solvent stability

High thermal stability and steam disinfected

Wear ability and excellent strength

Stable over a wide pH range

Narrow pore size distribution

Easy to be cleaned and regenerated

No chemical agent, no new sludge

Cold rolling emulsion waste water

In order to eliminate the thermal deformation caused by cold rolling in the rolling steel production process, emulsion should be required for cooling and lubrication, thereby there are lots of cold-rolled emulsion wastewater. JIUWU company has adopted UF ceramic membrane + MBR integration technology to treat cold-rolled emulsion wastewater, which has achieved very good results.

Mechanical processing of industry oily wastewater treatment

The waste liquid and washing wastewater discharged from the metal products during the mechanical processing mainly contain impurities such as oil, grease and metal ions, and are highly polluting to the environment. The ceramic membrane integration technology developed by the company can be used for the oily water treatment and has good performance in handling this kind of wastewater.

Edible oil

For most of the countries, Edible oil processing units is one among the major economic zones.

For edible oil refinery industries, “water” is the main component for the process. The wastewater from oil processing industries contains both organic and inorganic content, which are produced after various processes like degumming, deacidification, deodorization and neutralization steps. The wastewater will be also highly acidic and oily with Sulphate and Phosphate content that cause serious threat to environment and mostly the aquatic life.

With the increasing demand on treating wastewater from edible oil processing units, membrane technology including ceramic membrane bioreactor and RO /NF combined process has been applied to treat edible oil processing wastewater.

we will contact you within 24 hours.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español