High temperatureflue gas scrubber

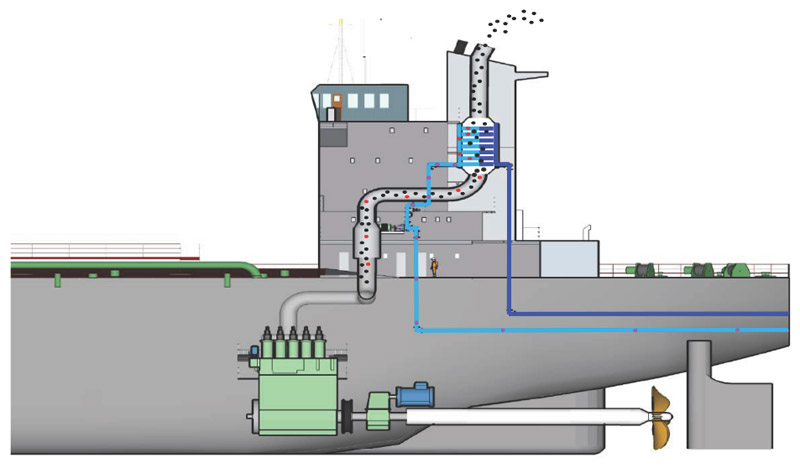

Ship engine exhaust gas scrubbing system

There are seven the world's top ten ports in China. Ocean-Going freighter brings a lot of pollution. Near the 400 meters of the coastline, engine exhaust is about 500,000 large trucks. So 60% of sulfur dioxide is from the ship in Shenzhen. Maybe you are not on the edge of the port, but you live on the edge of the river. There are more than 200,000 ships in China, which use the worst of heavy oil. You can pick up the black charcoal by hand on some dock.

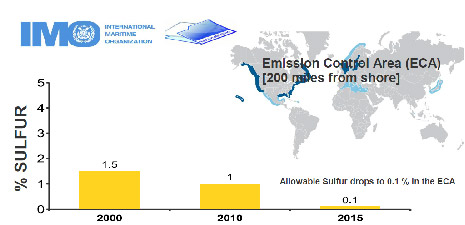

From Jan 1st, 2015, the International Maritime Organization (IMO) requires all ships sailing within the Sulfur Emission Control Area (SECA) to use low-sulfur oils containing less than 0.1% m/m of sulfur. Or the ship should use the exhaust gas treatment system or other technical methods to ensure that the total discharge of sulfides does not exceed 0.4g / kWh.

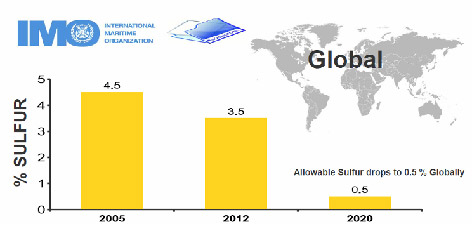

From Jan 1st, 2020, the International Maritime Organization (IMO) requires that ships sailing worldwide should use low-sulfur oils containing less than 0.5% m/m of sulfur, or use approved exhaust gas treatment systems or other technologies method to ensure that the total discharge of sulfide does not exceed 2.0 g/kWh.

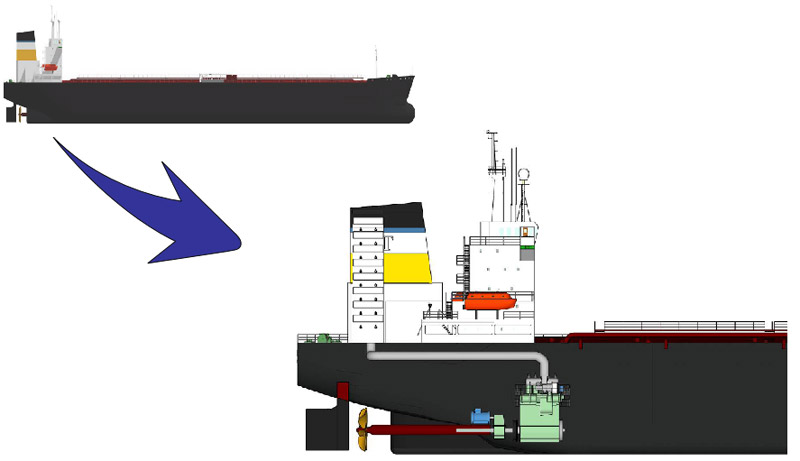

Schematic diagram of ship engine exhaust gas scrubbing system

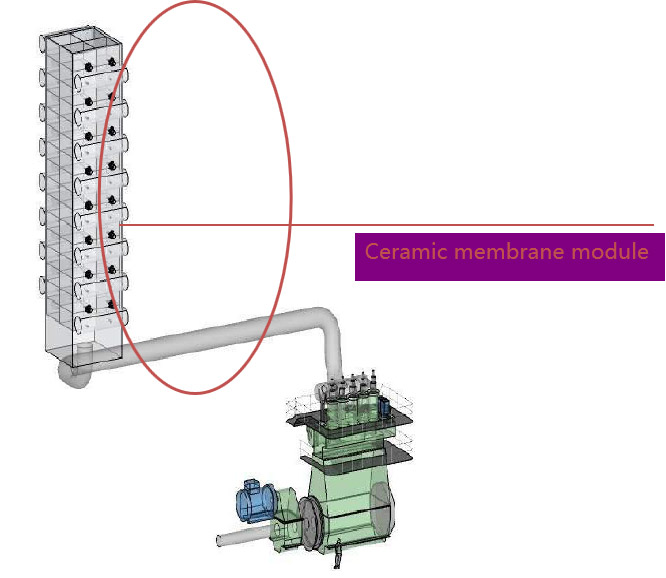

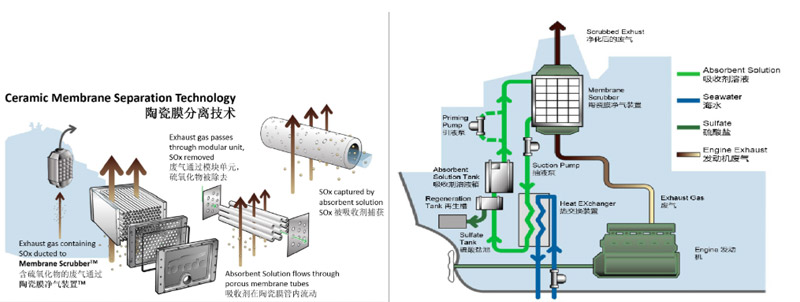

The desulfurization processor comprises a series of

ceramic membrane modules, an absorption liquid circulation system, a heat exchange system, an automatic control system and so on. The absorbing liquid is circulated through the inside of the

ceramic membrane tube, the exhaust gas passes through the membrane module, and the water vapor condenses on the surface of the membrane tube, and the sulfide in the condensate is absorbed by the liquid in the membrane tube.

Working principle of ship engine exhaust gas scrubbing system

On Jan 30th, 2016, marine exhaust gas desulfurization technology seminar with China's first set of Membrane-based Marine exhaust gas cleaning system visit ceremony was held in Nantong, Jiangsu.

The first domestic ceramic membrane desulfurization system was successfully installed

Nano ceramic membrane gas cleaning technology is currently the most advanced technology now. Compared with the 'sea spray’ equipment,

ceramic membrane technology is similar investment, with a 50% reduction in volume and a 30% increase in energy efficiency. This new technology equipment has just launched into the market and is immediately responsive. On December 10th, 2015, the “NOLHANAVA” Canadian 50,000-ton ocean-going freighter installed the equipment in Nantong.

|

Before treatment

|

SO2>1000ppm

|

|

After treatment

|

SO2<25ppm [0.1% S m/m]

|

Advantages of ship engine exhaust gas scrubbing technology

Advantages: small footprint, easy operation and maintenance, long service life, good treatment effect and easy transformation

1. Instead of the traditional spray method for flue desulfurization, the waste liquid volume is less, and the treatment effect is good;

2. Module design as skid, small footprint, easy installation and modification, and easy operation and maintenance of the system;

3. The ceramic membrane material is resistant to high temperatures, so the system can be operated at higher temperatures. At the same time, the membrane has good corrosion resistance and can be operated under harsh conditions such as acidity and alkalinity for a long time, and has a long service life;

4.The consumption of chemicals is less, the use efficiency is high, and it can be recycled.

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808