On September 11, at the "BAIINFO 2025 (4th) New Energy and New Materials Industry Seminar" held in Ningbo, Jiuwu Hi-Tech gave a wonderful introduction to its lithium lanthanum zirconium oxide (hereinafter referred to as: LLZO) and lithium aluminum titanium phosphate (hereinafter referred to as: LATP) oxide solid electrolyte series products.

Jiuwu's LLZO and LATP oxide solid electrolyte products have been recognized by multiple downstream application enterprises for their excellent comprehensive performance, and the powder performance has reached mainstream industry standards. The products have been successfully supplied in small batches to leading domestic battery cell enterprises. This marks a new step for Jiuwu Hi-Tech in its journey from research and development to industrialization in the field of solid electrolyte materials.

In recent years, Jiuwu Hi-Tech has always adhered to the innovation-driven development concept, continued to deepen its research on key new energy material technologies, and relied on its profound technical accumulation and innovation capabilities to continuously break through industry barriers and promote the industrialization of cutting-edge materials.

Solid-state batteries: the next generation of battery technology in global competition

The development of traditional liquid lithium batteries has reached its theoretical limits and presents significant safety risks, primarily due to the flammable liquid electrolyte. Solid-state batteries, due to their superior safety and theoretical energy density, have become a focal point of industry competition and a globally recognized next-generation battery technology.

Solid-state electrolytes are the key core materials for solid-state batteries. Oxide solid-state electrolytes, as solid-state electrolyte materials with great application prospects, have long faced industry challenges such as complex preparation processes, difficulty in improving ionic conductivity, and poor stability in mass production.

Overcoming the preparation technology of oxide solid electrolytes

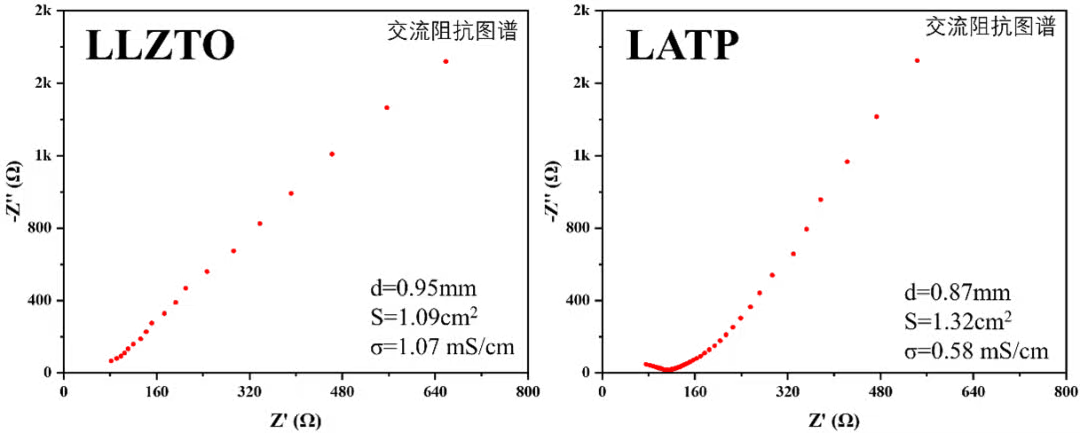

LLZO and LATP powder samples

After nearly three years of technical research, Jiuwu's R&D team has successfully developed a novel preparation process for oxide solid electrolytes (LLZO and LATP series powders), with proprietary intellectual property rights. The team has optimized properties such as ionic conductivity and water stability, resulting in improved material performance. Jiuwu has established a comprehensive supply chain for various product forms, including powders, slurries, and dense ceramic sheets, to meet the application needs of diverse customers and has achieved continuous and stable small-batch delivery.

High ionic conductivity

Jiuwu's independently optimized "low-temperature solid-phase-atmosphere sintering" collaborative process, combined with sintering kinetics control and multi-element doping modification technology, has improved the lithium volatilization problem of powders during traditional high-temperature synthesis, reduced production energy consumption, and achieved product batch consistency exceeding 95%, providing key technical support for large-scale industrial applications. The room-temperature ionic conductivity of the prepared LLZO series materials reached 1.0mS/cm, and the LATP also reached 0.5mS/cm, demonstrating excellent key performance indicators and reaching mainstream industry standards.

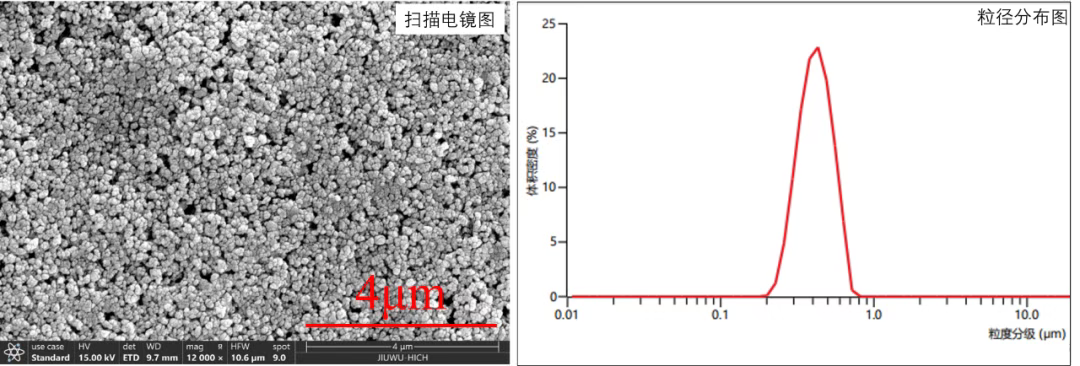

Narrow particle size distribution

In battery manufacturing, oxide solid electrolyte powders require small particle sizes to build a highly connected ion conduction network, ensure slurry uniformity, and optimize interfacial contact with the electrodes. At the same time, strict narrow particle size distribution can effectively prevent component separation during the coating and drying process of the slurry, avoid uneven thickness of the diaphragm and surface defects, and ensure the consistency and safety of battery performance. Jiuwu Hi-Tech uses exclusive grinding technology, combined with self-developed composite dispersants, to regulate the refinement process, controlling the powder particle size to D50 < 500nm and D90 < 900nm, ensuring that the powder is refined to the nanometer level while achieving an excellent narrow particle size distribution.

Performance stability

Leveraging nearly three decades of deep technical expertise in the sintering and chemical synthesis of inorganic ceramic materials, Jiuwu Hi-Tech has established industry-leading process expertise and R&D advantages. Jiuwu has a national-level green smart factory equipped with advanced production and testing equipment to ensure that oxide solid electrolyte materials maintain high purity and excellent crystallinity during large-scale production. Through long-term technical research and process optimization, the R&D team has successfully achieved high purity and excellent phase control for LLZO and LATP, while also maintaining excellent batch stability at the 100-kilogram level, providing reliable material support for the development of solid-state battery technology.

The powder phase is pure and free of impurities

Main application scenarios

LLZO and LATP possess intrinsic safety and promising application potential due to their excellent chemical stability, high room-temperature ionic conductivity, good mechanical properties, and low internal resistance. These materials can be used in the preparation of semi-solid-state and all-solid-state batteries, serving as cathode additives to enhance electrode performance or in separator coatings, significantly enhancing the battery's overall electrochemical performance and safety.

Main purposes

Diaphragm coating: Reducing electrolyte usage, inhibiting lithium dendrite growth, and enhancing battery safety.

Positive/negative electrode material coating: Enhance the material structure stability and improve battery cycle life.

Electrode blending: Improves ion conductivity, reduces interfacial impedance, and optimizes battery rate performance.

Electrolyte membrane: Matches high-energy electrode materials to enhance battery energy density

The stable small-batch delivery of LLZO and LATP not only demonstrates Jiuwu's strength in the R&D and production of advanced inorganic functional materials, but also provides reliable core material support for the industry, injecting new vitality into the practical application of solid-state batteries!

Looking forward, Jiuwu Hi-Tech will continue to increase its investment in R&D and industrialization of solid-state electrolyte materials. Leveraging green smart factories and proprietary innovative processes, it will comprehensively enhance the competitiveness of LLZO and LATP in large-scale production, performance optimization, and application expansion. At the same time,Jiuwu will actively establish partnerships with downstream companies such as diaphragm factories and battery factories, adopting an open and win-win atitude, to contribute positively to the development of the industry.

What are LLZO and LATP?

LLZO is a ceramic-like inorganic oxide material. Think of it as a strong and smooth "highway" for the lithium ions in a battery. While traditional liquid batteries are like flammable and explosive "blood," LLZO, a solid electrolyte, is inherently non-flammable, significantly improving battery safety and fundamentally preventing fires. Furthermore, its exceptional strength prevents "dendrites" that may cause short circuits during battery use, extending battery durability.

LATP is also an inorganic oxide material, and it is "classmate" with LLZO, but with distinct properties. Its biggest advantage is its stability in air and lower raw material costs, making it easier to produce on a large scale. It can replace unsafe liquid electrolytes and improve battery safety.

+86-25-58849045

+86-25-58849045

+86-25-58749295

+86-25-58749295

jiuwu@jiuwu.com

jiuwu@jiuwu.com

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory) Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

No. 9 Park Road, Pukou District, Nanjing City (Sanqiao Factory)

English

English 한국어

한국어 français

français русский

русский Español

Español