TEA EXTRACT

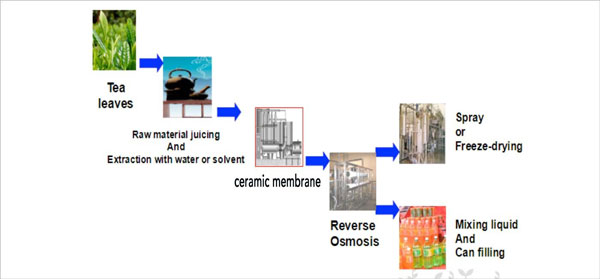

With the emergence of tea drinks and tea products, tea polyphenols or instant tea powder as a major ingredient demand surge. How to improve the quality of their products and reduce production costs, has become the focus of attention.

In traditional plant extraction methods, the tea polyphenol is seriously lost, and the tea flavor is also a great loss. And the tea juice made from the two kinds of raw materials is not clarified and easy to precipitate.

As the increasing development of

ceramic membrane technology, membrane separation and membrane concentration become the best choice for extraction and concentration of heat-sensitive substances such as tea juice, fruit juices and vegetable juices.

Tea juice is concentrated by membrane at first(can also directly produce instant tea powder or hook on the tea drink) and then extracted polyphenols, although one-time investment is slightly larger, but the operating cost is lower than the vacuum concentration method, and the amount of extraction solvent is reduced , product quality is significantly increased, reducing the phase transition of active ingredients in tea (such as EGCG) and the loss of aroma compounds in tea. Caffeine, tea polyphenols, theanine, instant tea powder or direct hook into tea drinks can be directly produced.This process has less emissions of pollutants with good technical and economic advantages.

Advantages:

-

Effectively retain the functional active components in tea

-

High stability of final products

-

Functional effective extraction rate and purity are high

-

Concentrate from membrane has good colour, smell and testing

-

Long work life for membrane filter

-

Lower cost of manufacture

-

Membrane is easy to be regenerated by normal chemicals

-

Easy maintenance which will save much labour cost

-

Reliable operation with PLC control

PLANT AND ANIMAL PROTEIN

Soybean milk protein concentration

Compared with the traditional evaporation process,

ceramic ultrafiltration process can get higher solid content, at the same time can save energy, and can achieve cleaner production.

Soybean protein isolate(SPI) extract

The introduction of advanced membrane separation technology can effectively improve the separation capacity of plant extracts, increase the protein content, reducing the proportion of moisture in the bean dregs. Ceramic membrane can effectively meet process requirements,which can make solids content up to 25%.

However,whey wastewater from SPI production has become a common constraint in the deep processing of soybeans. The use of membrane separation technology can effectively control the environmental pollution, recycle recoverable whey protein from whey wastewater which brings a new economic growth to soybean factories.

Soy oligosaccharides recovery

Soy oligosaccharides are the main by-products of soybean food processing, which are abundant in the supernatant after the production of soy protein isolate. To recover soy oligosaccharides, nanofiltration can get more satisfactory results.

Soy active peptides

Ceramic membrane separation process is applied to the separation and purification of soybean active peptides by the fermentation method. The permeate is clear and transparent and has an orange-red color. The vast majority of bacteria in the fermentation liquid and the insoluble macromolecule proteins and colloid are entrapped and removed. Permeate without sediment phenomenon is realized for a long time. At the same time, the method of continuously adding dialysis water can collect effective dissolved components in the raw material liquid as much as possible so that the yield of the soluble polypeptide reaches more than 95%.

Dried porcine solubles (DPS) extract

The raw material of DPS is animal intestinal mucosa.

The small intestine of fresh animal in the slaughterhouse will scrape the small intestine content (mucous membrane) when it is processed into semi-finished sausage casing, and the intestinal mucosa is mainly used to extract heparin sodium. The intestinal mucosa after extracting heparin sodium is the raw material for the processing of intestinal membrane protein.

The application of membrane process has the following advantages:

The application of membrane process has the following advantages:

-

Fully recovery protein

-

Product purity has been improved

-

Reduce the cost of drying

-

Improve product quality

-

Convenient and simple operation

PLANT PIGMENT

Plant pigments include a variety of different kinds of molecule, porphyrins, carotenoids, anthocyanins and betalains.

The traditional method of extracting plant pigment is:

The traditional method of extracting plant pigment is:

First, crude extract is carried out in organic solvent, then refined with resin or other processes, and then evaporated and concentrated at a low temperature .The process is complex, difficult to control, has large amount of organic solvents and resin dosage, consumption of acid and alkali, high operating costs, polluted environment, unstalbe pigment quality , low color value.

Application of membrane separation and purification process can simplify whole process, save organic solvents. Ultrafiltration process can remove protein, starch and other impurities, and then desalinated by nanofiltration to remove small molecules, while concentrated. Automatic control can be achieved, greatly reducing extraction costs, pigment quality and stability and high color value can be satisfied.The entire process does not add any additives, is the real green technology. It is also applied to the production of herbal extracts.

Call us on:

Call us on:  Email Us:

Email Us:  No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808

No. 9 Yuansi Road, Pukou, Nanjing, Jiangsu, China 211808